Electrical substations frequently face challenges from a number of sources. These include vandals, intruders, hazardous weather, and high energy demand periods. On top of this, there’s the difficulty of the substations being unmanned and often remotely located. This makes them harder to protect from intrusion, theft, and sabotage. Substations are vulnerable points in the electricity grid and therefore critical to society. This makes it even more important to be able to remain in control.

As a result, the utility sector is increasingly focused on addressing these issues to ensure the uninterrupted supply of energy to both residents and businesses. This requires a combination of monitoring for alerts of a potential breach as well as signs of equipment dysfunction.

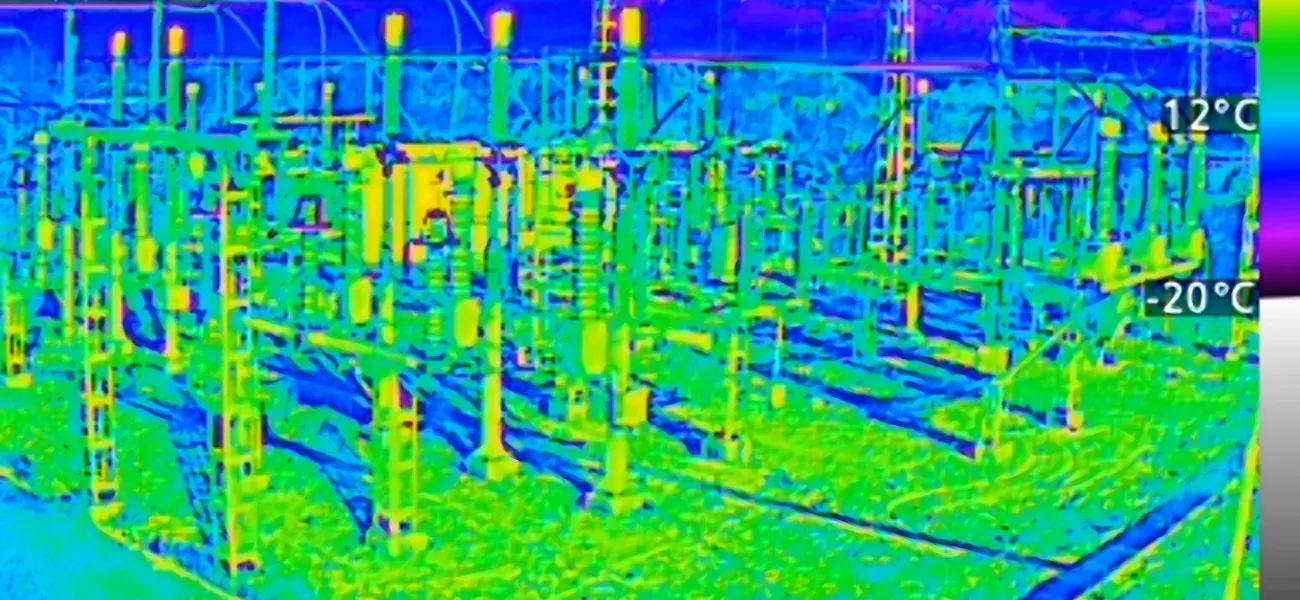

Monitoring continues to be a largely manual job, but a growing number of energy organisations have been looking at ways to make this safer, more efficient, and actionable. Thermal imaging can be used to support you in these efforts, and provide continuous, accurate monitoring of substations to not only improve security and safety, but also support operational efficiency and continuity.

Benefits of thermal imaging over visual cameras

Thermal imaging requires no light. At all. Thermal cameras allow you to see in complete darkness and are equally as operational in daylight hours. This differentiates them from visual cameras which require reflective light for the sensor to pick up an image. Thermal imaging is created by sensors detecting temperature differences in the heat energy an object emits, and then translating this into image details. Thermal imaging coming from thermal cameras, or more correctly thermal sensors, is as accurate in pitch black, fog, and camouflage as on a bright sunny day.

As new sensors, materials, and improved calibration make thermal cameras more affordable, reliable, and versatile, thermal imaging is becoming increasingly available. While thermal cameras are mainly used for surveillance purposes by detecting objects like humans and vehicles, there are other possible areas of use. When it comes to monitoring equipment and production processes a thermometric camera gives you the ability to calibrate the heat display with numerical data, in other words, temperatures. It sends alerts when the temperature goes out of the pre-set range, which can then be investigated. When looking to improve your operational efficiency, this ability fits well with temperature monitoring of critical assets and equipment.

Thermal imaging improves operational efficiency

Hand-held thermography cameras are used in substations to detect heat and provide a thermography readout of the energy being emitted. These checks are carried out at three-to-six-month intervals. While hand-held measuring requires physical visits to the site, a thermometric camera permanently mounted on the site introduces the possibility of having an alternative ahead of in-person checks, by monitoring the relevant equipment day and night and all year round.

Thermometric cameras can both create alarms of rising temperatures and routinely conduct checks of critical areas which can provide you with a greater understanding of the situation. The 24/7 monitoring of a site using thermal imaging helps you to catch a developing problem before it gets worse and more costly. This early intervention can therefore positively impact ROI.

Thermometric cameras are set to become an essential piece of equipment for trend analysis, operational efficiency, and continuous monitoring to maintain your substations and extract valuable operational data.

Thermal imaging boosts threat detection

Due to the critical role that substations play they are subject to a variety of threats, including cyber-related attacks. Cameras with built-in cybersecurity features help prevent hackers from infiltrating your networks and disrupting processes. However, other threats take on the more physical form of intrusion, such as theft and sabotage.

Compared to visual cameras, using thermal cameras to detect potential intruders provides you with more reliable detection and shape recognition. This is achieved by combining high image contrast with motion detection. As a result, the false alarm rate can be kept down, with fewer unnecessary responses and actions by your personnel.

Thermal cameras can help you detect activity on, and just outside the perimeter, day or night. The support in perimeter protection can play an important role in your fence line solution. This solution could consist of a thermal camera with an analytic detecting a potential intruder, which triggers a PTZ camera to have a look and give a good visual of the intruder, as well as track the intruder around. Audio deterrents like horn speakers or light deterrents like strobe sirens can also be added to this solution to tackle intrusion threats.

While using sound detection, the devices can alert you of a potential attack on the site which will then enable your security company to check the scene. For example, if a transformer has been attacked the alert provides an early opportunity to stop any oil spillage and the collapse of the machine.

Another threat on the rise is drones. Drones are increasingly being used by malicious individuals to monitor substations, deliver payloads, and cause your substations to fail. Drone detection is done with partner hardware and software. As with a visual camera, a thermal camera can complement this by providing you with a view of the drone.

Substation security for safety

A greater focus on maintaining substations also means more monitoring of the site. Overheating increases both fire and explosion risk which thermal imaging and thermometric cameras can monitor equipment for. This improves the safety of your personnel by providing an overview of the state of the machinery before sending engineers on site.

Thermal imaging also supports safety through its capabilities of detecting trespassers and triggering other devices in the security solution to deter any unwanted activity with audio and lights. Beyond security for the site and valuable assets, deterrence also serves to protect the intruders themselves. This is not limited to the intruders with malicious intent (i.e., theft or sabotage) but also trespassers such as kids or teenagers who enter your substation out of curiosity or simply not knowing any better. These trespassers otherwise risk being killed or seriously injured among the high voltage equipment.

Building resiliency on-site

Failure of multiple substations in one area would create a multitude of societal and business operational problems down the line. It is therefore critical to build in extra layers of security into your substation sites to improve resilience to potential threats and problems. This is where thermal imaging can add the most value.

Thermal imaging is key to improving the maintenance, security, and safety of your substations by monitoring areas in and around the premises 24/7. Your ultimate goal is to deter potential intruders and spot equipment anomalies at the earliest stage to avoid unexpected shutdowns or a cascading event. Thermal cameras can act as first responders to achieving this.